What causes demagnetization when using powerful magnets

Powerful magnets have requirements not only for the working environment, but also for the indoor environment. Compared with ferrite magnets, aluminum nickel cobalt, and samarium cobalt, its magnetic function greatly surpasses other types of magnets. Neodymium iron boron magnets can absorb 640 times of their own components, so neodymium iron boron is often called by outsiders. For strong magnets, strong magnets can be magnetized and demagnetized, because the magnet itself is more or more magnetic. So what causes demagnetization when using powerful magnets?

However, in normal times, we still have to choose the AC demagnetization method for better effect than the high temperature demagnetization method and vibration demagnetization method. The demagnetization efficiency is higher, and it is now the most used method in industrial production.

We can draw up a certain method for demagnetization according to the use of powerful magnets

High temperature demagnetization method: The primary operation of the high temperature demagnetization method is to put the magnet into a high temperature furnace for heating. After high temperature treatment, the magnetism of the strong magnet will be removed, but during the heating process, the effect of high temperature will directly cause The structure of the object inside the magnet has undergone drastic changes.

Therefore, this method of demagnetization is generally used for invalid and retracted magnets. The operation of this method is very simple, which is to vibrate the strong magnet strongly and vigorously. After the vibrating operation, the internal structure of the magnet is changed, and then the physical property of the magnet is changed. This method is generally used for this demagnetization method. The effect is not great, only a small amount of demagnetization can be used temporarily.

This demagnetization method is to put the magnet into a space that can generate an AC magnetic field. After the AC magnetic field is disturbed, the internal structure of the magnet will be disrupted, and then the demagnetization effect can be achieved. This method is more common. Method of demagnetization.

Why can't a strong magnet be made into a very thin shape

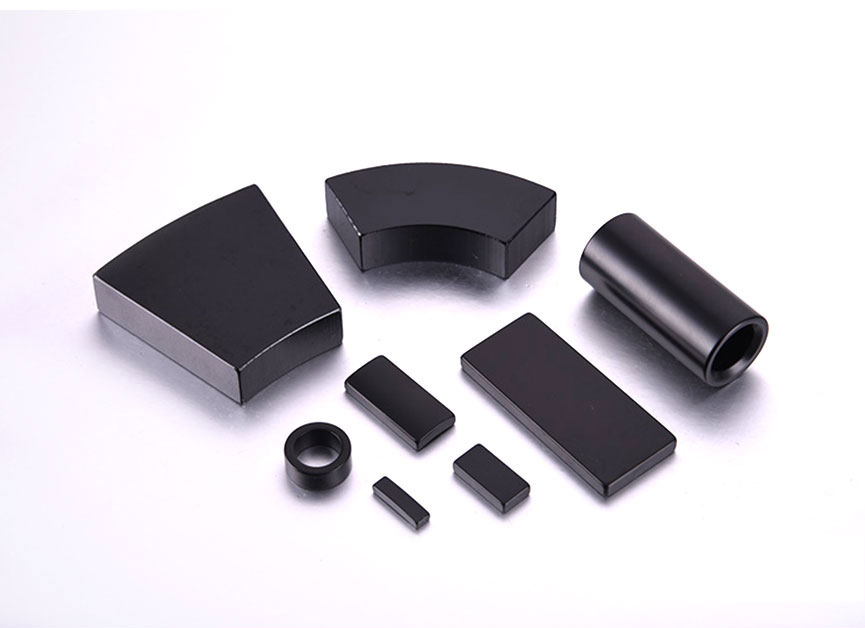

Powerful magnets have different appearances and specifications, ranging from thick to thin, long and short. It is simple and disorganized. In the many years of experience in the production of magnet manufacturers, the thickness and length of the magnet are inevitable planning. It is not as much as you want. It must meet the characteristics of the magnet itself.

Whether a strong magnet can be made as high as possible, or how thin it can be opened, in fact, this is all possible. But it’s very large. It’s very magnetic and it’s not convenient to use. Whenever you encounter a ferrous product, a strong magnet will attract it. It’s easy to smash the magnet, and it will hurt when you are not optimistic. People, so it’s not easy for customers to suggest that customers use large ones; secondly, when the magnet is too thin, it is also very inconvenient to apply, because it is a rare earth, which is very simple to break, and the magnet is very strong. Simplicity leads to waste of production costs.

At this stage, there are a lot of products on the market that need to install powerful magnets. Such as TWS wireless Bluetooth headset magnets, fitness sports wireless Bluetooth headset magnets, high-end packaging magnets, mobile phone charging cable magnets, due to the use of plastic components and powerful magnets, many well-known brand manufacturers and some wiring harness processing factories are producing When manufacturing this product, you will encounter problems such as magnet safety.

When purchasing a magnet, it is necessary for the manufacturer of the magnet to distinguish the N-pole or S-pole optical rotation of the strong magnet first, so as to avoid the poor function of the strong magnet due to the optical rotation. As a result, the manufacturing cost of the magnet is increased, and the productivity is reduced. Although this kind of method can distinguish the optical rotation, it still cannot completely avoid the situation of opposite polarity.

sales00@jlmagnet.com

sales00@jlmagnet.com