A magnetic pickup is a unique construction that allows an object to have its weight placed directly on its center-peripheral board. These are popularly used by consumers that like to put heavy objects on their vehicles. What this means is that you can mount anything onto your vehicle without any need for additional hardware, tools, or brackets. The weight of these objects is evenly distributed over the board. In this way, it acts as a simple counterweight for your vehicle's stability.

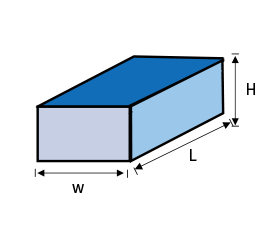

As compared to the usual flat disc magnets of the same size, they receive more surface area, which results in a much stronger magnetic attraction hence the much higher pull force of block magnets ranging from 0.6 lbs to just over 1,082 lbs! block magnet sold by several reputable suppliers of car accessories. Block magnets come in several varieties depending on the type of materials that they are made from. Also, the different types come in various colors and sizes to best suit any preference.

There are several types of block magnets including neodymium, ceramic, iron, and stainless steel. Neodymium magnets are the most popular because of their unique design. They consist of two metals that are magnetized and are used to prevent friction. This makes it possible for the weight of the object to be evenly dispersed over the entire board.

Ceramic block magnets can come in a number of shapes and sizes such as hexagonal, octagonal, cube, rectangular, and circular. All these shapes come in standard and custom sizes, making it possible to effortlessly choose the correct size for the application. Some of these cube magnets also feature cutouts for different uses such as connecting two bars or plates or holding a flag, a cross, or other significant figure. One of the most popular sizes of these neodymium bar magnets is the 10 inch cube magnets. These cube magnets have many standard features that make them easy to handle. They usually feature a smooth surface for easy grip as well as interlocking edges to make it convenient to place them in one another.

Iron block magnets are the next most sought after type of magnetic material for car magnets. They have the highest strength rating among the three and are commonly used for industrial applications. They can withstand heavy loads and can retain their shape even under pressure. They also feature unique design features such as internal pulling coils and unique external pulling bars. Some of these iron block neodymium magnets even feature rare earth magnets for maximum benefit.

The third type of magnetic material used for car magnets is the rare earth metal neodymium. While iron blocks have the highest strength rating of all the materials, they are a lot more expensive than neodymium magnets. Neodymium magnets, however, are the strongest permanent magnetic material available and are capable of handling the toughest pulls. The rare earth metal can also withstand high temperatures and is commonly used in microwave ovens.

Aluminum ndfebrictons are an inexpensive choice when choosing a magnetic material for your car. They are very lightweight and have the same strong pulling power as iron blocks. Some people also prefer them because they are easier to install and remove than most of the other magnetic materials. They are not as strong as rare earth magnets, but most of them can survive in most car applications. They do not have the special features found in neodymium blocks.

A common feature of neodymium blocks is that they are difficult to handle. They are much stronger and thus, you would be advised to use these blocks sparingly in any automotive application. The strength rating of neodymium bars is much less than that of the strong neodymium magnet. This makes them much less likely to be an appropriate choice for handling strong neodymium bar magnets.

When selecting a strong neodymium magnet, it is important to check for block designs that can be interchanged easily. Block styles like those found on many common iron blocks are difficult to switch out. Many of these blocks are solid and may not be easy to change out when new ones arrive. As a result, they become useless after only a few uses. This makes these strong neodymium magnets less desirable and much less useful for automotive applications.

The best way to deal with these types of weak magnets is to avoid them altogether. It is far better to select a strong and sturdy design that will last longer when you need to change the design on the fly. You can even find these designs online at extremely low prices. These are the best ways to deal with weak, block magnet handling.

sales00@jlmagnet.com

sales00@jlmagnet.com