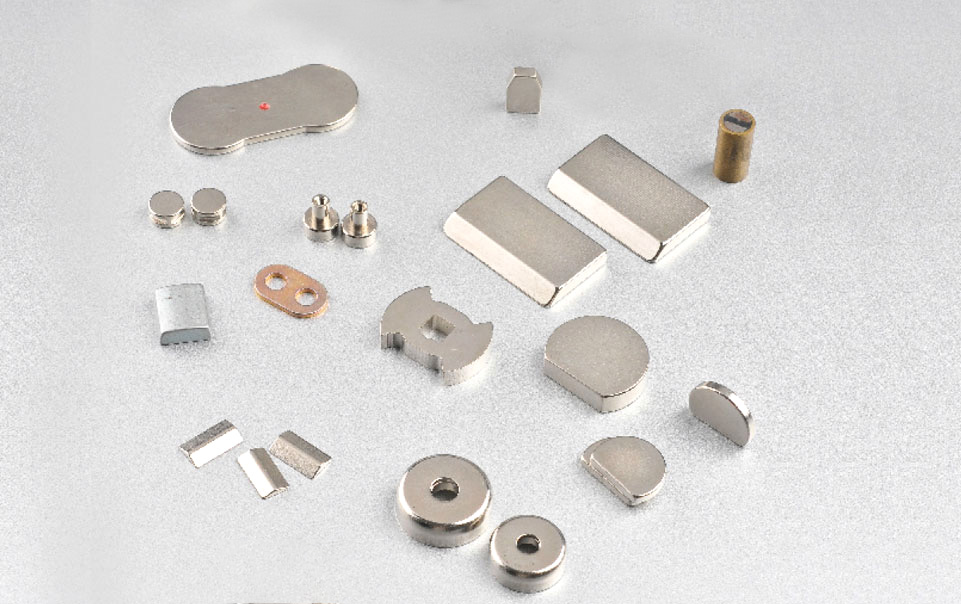

Neodymium Magnets is used extensively in applications requiring high strength and durability. Due to the extremely fine feature of Neodymium Magnets, they tend to have a low holding force when compared to other materials such as Stainless steels. The material is available in several different shapes and sizes and various impurities can be bonded to Neodymium Magnets in custom shapes. The custom shapes of Neodymium Magnets can be used in hundreds of applications in industries such as aerospace, automotive, medical, power generation, communications, heating, power, consumer products, military and others. Some of the custom shape varieties of Neodymium Magnets are:

Custom Shape Neodymium Magnets is produced through the use of solid boron nitride in a solid, powder-coated dielectric shield. This method of producing Neodymium Magnets has many advantages. The most noticeable advantage of this method of manufacturing Neodymium Magnets is that it produces a custom shaped permanent magnetic field that is highly flexible. Neodymium Magnets with custom shapes will not degrade over time and they will resist most common abrasion and impact loads. In many cases, this type of magnetic shielding is coated with a heat resistant varnish substance to protect against friction and abrasion.

Neodymium Magnet Plated: Neodymium Magnets, which is coated with a plating process called nVDY or Nondestructive Displacement Yield is a very common practice for the production of the majority of Neodymium Magnets. The plated laminated neodymium magnet will have a polished finish that provides a mirror-like appearance to the Neodymium Magnet. The Neodymium Magnet will then be mounted on a metal core such as a silver plate. The Neodymium Magnet will be then placed within an Eddy Current Device. Typically the Neodymium Magnet will be in a high-conducting crystal structure with a thin aluminum cover.

Neodymium Magnets is pressed or rolled into sheets and they are then coated with a magnetic field coating. While most commonly referred to as pressing Neodymium Magnets, they may also come in a rolled edge state called cut Neodymium Magnets. While pressing Neodymium Magnets are pressed into sheets they are available in a flat-surface and a round-edge surface. The flat-sided Neodymium Magnet is more commonly found in industrial applications and the round-edged Neodymium Magnet is typically used for household applications. In addition, both flat-sided and round-sided versions of the Neodymium Magnet can be custom designed for the specific application.

A number of different advantages exist with the use of Neodymium Magnets in the manufacture of electric motors. For example, the Neodymium Magnets is generally well suited for low voltage operation. Electric motors that make use of permanent magnets in their operation operate modes are ideal for applications where high power is needed. This type of motor can generate more power when it is operating at higher temperatures. Although Neodymium Magnets may not generate the maximum power output of other forms of electric motors, they are well suited for applications that require a large level of torque.

Neodymium Magnets are also used to prevent corrosion. This is beneficial for shipbuilders and other industries that operate ships at sea. As ship parts such as gears, blocks and motors are exposed to salty waters or chemicals which can corrode certain materials, they can be effectively protected by using Neodymium Magnets. The use of Neodymium Magnets in this context ensures that the gears and other components will remain durable and effective even under harsh conditions. Moreover, the use of Neodymium Magnets in automobile manufacturing means that car owners and drivers will be able to enjoy greater safety features and enhanced durability of the vehicle.

One of the numerous unique attributes of the Neodymium Magnets is that they contain an abundant supply of rare earth metals. This makes them particularly suitable for applications that require the use of rare earth metals. Some of the common uses of Neodymium Magnets include:

Many industrial, scientific and medical laboratories make use of Neodymium Magnets. Since the material has the ability to support electrical currents, it is used in a number of power generating and other electrical applications. For example, in experiments regarding the production of energy, Neodymium Magnets are often used along with copper and aluminum to create a hybrid energy generator. Other common uses of the Neodymium Magnet include: curing of medical wounds, magnetic therapy, controlling the size of magnets and controlling the alignment of various shapes and tubes.

sales00@jlmagnet.com

sales00@jlmagnet.com