Rare earth metal that has high magnetic properties is magnetic steel. It is an alloy of iron and magnetized tin. It is a very versatile metal and because it can be used for precision working it is used in electronics, automobile repair, dental work, aerospace applications, and industry. It is one of the strongest and most durable materials available today and comes in many different shapes.

In addition to the special shape of the rare earth magnet, it also has several other special characteristics. Like other magnets it is capable of holding two opposite polarity poles very well. In fact, it is almost impossible to remove a magnet from its natural state. Although these unique properties of neodymium iron boron magnets make them in high demand in the industry they are also quite expensive. Some people are willing to pay a pretty penny for them but there are others who consider it an investment. The main difference between an investment is that with an investment you can ride out the recession while a rare earth metal is only valuable if the market is booming.

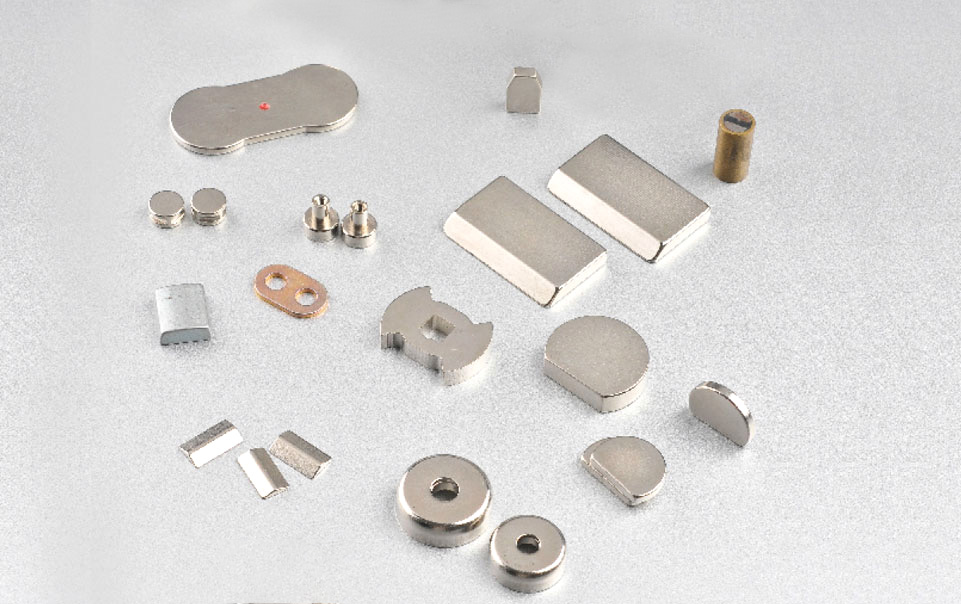

There are a variety of different alloys of rare earth magnets available today. Although neodymium magnets are strong and durable there are also other magnet materials available today. There is one particular magnet materials available that can hold a large number of poles and this is what makes these special shaped magnets so popular. They are also available in a number of different shapes and sizes.

One of the most common forms of these rare earth magnets is a custom made design that is created by a manufacturer. Some people like to buy the pieces and then have them customized. A manufacturer can cut them to any shape or size and then weld them together to create a one of a kind design. Another way that a manufacturer can customize these pieces is through the process of smearing and etching. This can be done on a variety of different grades of rare earth magnets.

Other rare earth elements that are used in these magnets include barium, strontium, titanium, and magnesium. Barium is commonly used because it is very strong and can be used for a variety of applications. Strontium is extremely strong and can be used for applications such as surgical sutures. Titanium and magnesium are used for many of the same reasons and they are also extremely strong. When looking at the various rare earth magnet materials that are available, you will find that there are many different grades and alloys that are used in these pieces.

One of the most common metals that is found in the magnetic materials that are made by companies. This metal is extremely hard and can be used to create some of the strongest magnets possible. Because of its hardness tungsten is often combined with other metals to create the rarer magnets. Some examples of these are cobalt and nickel alloys. The nickel alloys are used because nickel is very hard and can be combined with other elements to create the best rare magnets possible.

Other common metals that are used to create these rare earth magnets include aluminum and tin. These are combined with other compounds to create stronger magnets and even stronger magnetic properties. Many of the rare earth magnets that are created are shaped in the form of animals. For example, there are bird-shaped magnets. There are also shapes that are geometric like circles, squares, and ovals.

To determine the strength of the magnetic fields created by the rare earth magnets, you will need to know what the values of their magnetism are. One way of doing this is to compare the values that are given to you by each company. Another way of doing it is to measure how far off each magnet can be from a table that has a similar strength level. Most companies Jinlun Magnet (jinluncicai.com) will also have their own unique magnet ratings that are based on these measurements. The different magnet grades are determined by the amount of resistance that the material that the magnet is made of can provide.

sales00@jlmagnet.com

sales00@jlmagnet.com